Shipping calculated at checkout

HOW WE MAKE YOUR CLOTHES

HADES is committed to designing and making clothes that are made to last. Our ambition is to create beautiful knitwear and clothing that enriches your life and that you will cherish for years.

For every piece of HADES clothing we will have carefully considered the material in terms of longevity, wearability and comfort.

Our jumpers and scarves are handcrafted in Hawick Scotland, our cardigans are knitted in Spain and our skirts are constructed in England. When you buy HADES pieces you can be assured that it has been made using quality materials, pieced together with exceptional craftsmanship and created in a way that is fair to people and the planet.

HOW WE MAKE YOUR KNIT

It all starts with the yarn. Cloth determines the life of a garment. Our knits are made in 100% lambswool.

The yarn of our jumpers and scarves comes from a family run mill located in the Yorkshire Pennines in England.

The wool of our cardigans is from a historic mill, originating in 1817, in the heart of the Vicenza province.

Read more

Many wool garments are not made from 100% pure wool but are mixed with acrylic, viscose, nylon and polyester which are derived from petroleum. We only ever work with pure fibres, which means our jumpers last longer than synthetic fibres and don't shed plastic microfibres into the oceans.

Our jumpers, scarves & gloves are knitted and assembled in a small, independent manufacturers in Hawick, Scotland.

The wool industry in Hawick originated in 1771. The team we work with are ambassadors of the craft, keeping artisan practices alive.

Our cardigans are assembled by a small manufacturers in Cuenca, Spain.

The knitted pieces of our knits are crafted using advance Japanese & German machinery.

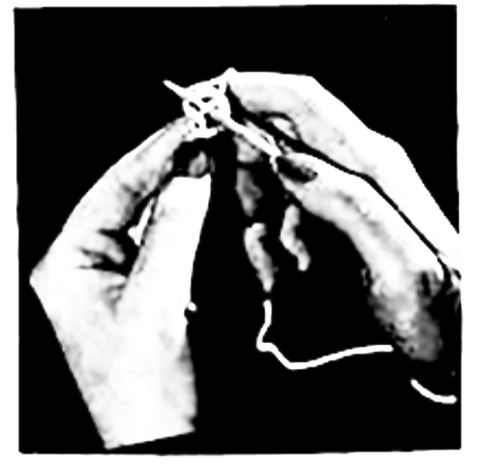

The individual pieces are then hand sewn together with exceptional precision.

HOW WE MAKE YOUR CLOTHES

Our skirts are made from natural fibres or deadstock fabric.

Natural fibres are breathable and better for the environment. Deadstock fabric would otherwise go to waste, by giving this fabric a second life it reduces waste and contributes to a circular economy, which is less damaging to the planet.

Read more

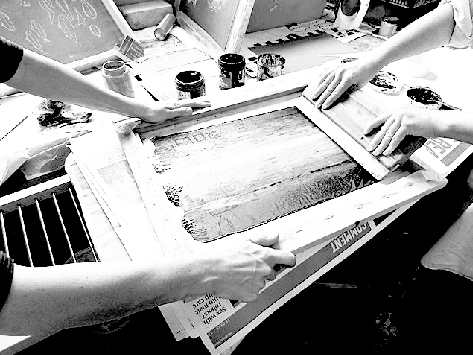

All screen printed designs are originally printed in England.

The process involves pressing the ink or dye of the design onto the fabric using a thin sheet of mesh, and then using a small blade or squeegee to ensure that the ink transfers through the mesh.

Screen printing is a historic technique, originating in China around 960 AD, that can take years to master!

For the construction of the garment we work with a small atelier in Somerset, England. HADES is proud to know the names of everybody who has constructed our pieces.

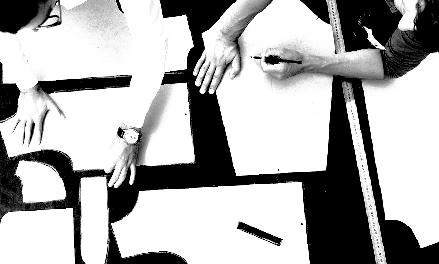

First the pattern pieces are made to create the desired silhouette and garment fit.

The fabric is cut out and sewn together with great precision.

Details are added to each piece including trimmings, waistband and potential darts and pleats.

The process of crafting each piece is lengthy and much of the work is done by hand. HADES champions craftsmanship, it is culturally and socially important that craft and industry in these regions are supported to safeguard its future.

Clothes have the potential to enrich and improve our lives, in order for them to do this we must begin again to appreciate how they are made, who makes them and the materials that they are made from. HADES believes there is beauty and power in craftsmanship.

As HADES grows and we add new product categories, wherever possible we source from Scotland & England.